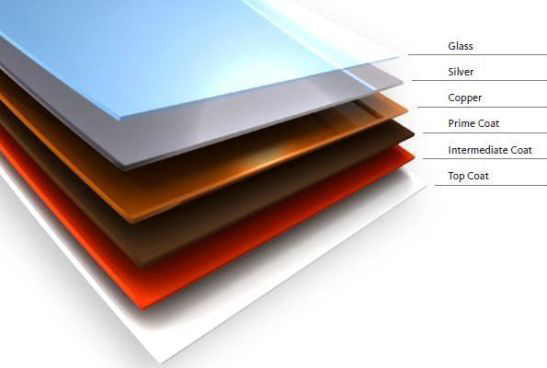

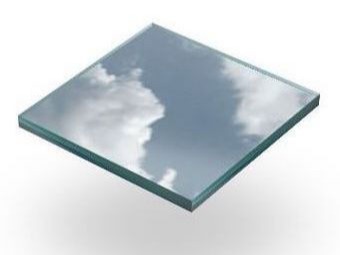

Normal Silver Mirror

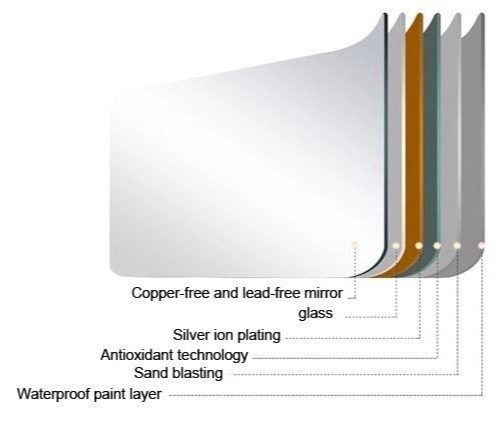

Copper Free & Lead Free Mirrors.

Aluminum is a popular choice for mirror coatings because of its reflectance. With the highest reflectance of any metal in the ultraviolet and infrared spectral ranges, aluminum only falls behind silver in the visible light and near-infrared ranges. Bare aluminum can be used in optical mirrors for telescopes in space to achieve larger bandwidths of light. Unfortunately, the natural creation of aluminum oxide can reduce the reflectiveness of the aluminum coating. To counteract this, additional protective coatings can be applied over the aluminum.

A natural barrier oxide layer can form over aluminum mirrors, protecting it from further corrosion. Unfortunately, this barrier is not easy to clean and can be altered based upon other environmental factors. Because of this unreliability, protective coatings are often placed over the bare aluminum. This usually involves a dielectric coating that successfully protects the surface from damage. However, this could potentially reduce the reflectance of the aluminum. An atomic layer deposition technique or another deposition method could potentially improve protection while limitedly effecting mirror reflectance.

Though the presence of oxygen may cause aluminum to corrode, even if the aluminum does have an additional protective coating, there is hope that future optical mirrors used in an astronomic application could be positioned far enough from the Earth not to be impacted by these environmental factors. In this case, mirrors with protected aluminum coatings may be well-preserved and function without issue for long periods of time.

RUNTAI Aluminum Mirror is produced through Horizontal Productionline, which is the most advanced production equipment for coating aluminum, so our aluminum mirror is best quality, that’s suitable for any kind of processed and edgework., such as:

Decorative Furniture Mirror, Art Mirror, Bathroom Mirror, Beveled Mirror and other Processed Mirror etc. Quality Aluminum Mirror is usually coated by two layers of paints. We can offer both Single Coating and also Double Coating as per customer requirement.

Our Aluminum Tinted Mirror can be produced in Clear as well as Colored Mirror with various color like Gray, Bronze, Green, Blue, which is produced by vacuum coating a layer of aluminum on the tinted glass which produces different and nice decorating effect.

Sheet Aluminum Mirrors:

Thickness: 1mm, 1.3mm,1.5mm,1.8mm, 2mm, 2.3mm, 2.5mm, 2.7mm

Float Aluminum Mirrors:

Thickness: 1.5mm,1.7mm,1.8mm, 2mm, 3mm, 3.5mm, 4mm,4.2mm, 4.5mm, 5mm, 6mm, 8mm

Regular Sizes: 500*700, 600*900, 1000*700, 1000*800, 1220*900, 1220*914, 1220*1000, 1830*1220, 2440*1830, 3300*2140, 3660*2140 to the maximum.

we can do according to customer requirements for the back color and single and double coating of the layers of the Paints while processing Mirrors if they

can meet our MOQ (Minimum Order Quantity)

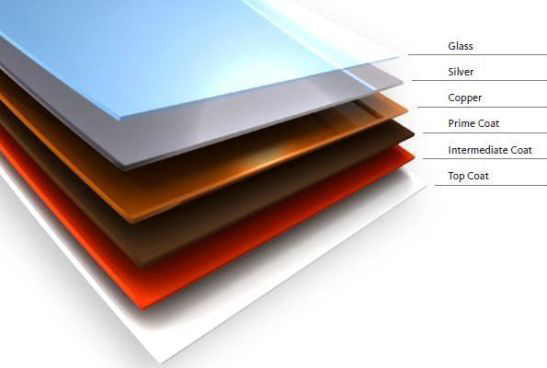

Silver is an excellent metal to use for plating. Silver is also used a more affordable alternative to gold plating. In astronomical optical mirror application, silver coatings provide benefits to primary, secondary and tertiary mirrors because of its high reflectance and lasting durability.

Enhanced protective silver coatings are being explored to provide maximum reflectivity while improving the lifespan of the silver base. One prospective process that would create stronger corrosion barriers is through plasma-enhanced atomic layer deposition, using aluminum-oxide as the top layer that acts as a barrier to help protect against corrosion and maintain reflectivity. Results of testing show that these added layers successfully protect against corrosion and moisture. These plasma-enhanced barriers can be applied to optical mirrors that require high reflectivity and absorbency.

Benefits of Silver Coated Mirrors

Compared to other plated metals, silver has the most applications and is found throughout nearly every common industry. Classified as a noble metal, silver possesses many inherent benefits that make it a versatile plating material. For years, the process of silvering was applied to coat the surface of glass to create mirrors. Silver coatings are ideal for observing all wavelengths of light, offering high reflectivity and low emissivity that is especially useful for an infrared application.

Thickness: 1.5mm,1.7mm,1.8mm, 2mm, 3mm, 3.5mm, 4mm,4.2mm, 4.5mm, 5mm, 6mm, 8mm

Regular Sizes: 500*700, 600*900, 1000*700, 1000*800, 1220*900, 1220*914, 1220*1000, 1830*1220, 2440*1830, 3300*2140, 3660*2140 to the maximum.

we can do according to customer requirements for the back color and single and double coating of the layers of the Paints while processing Mirrors if they

can meet our MOQ (Minimum Order Quantity)

Benefits

Silver offers high performance in nearly all of its properties

Superior light reflection of 94% on 4 mm thickness (Using Ultra Clear Float Glass)

RUNTAI Mirrors offers superb reflection and clarity

Excellent resistance to natural atmospheric corrosion

Higher corrosion resistance and improved protection to chemical attack from cleaners

Environmentally friendly manufacturing process produces less waste and ensures easier onward recycling

Manufactured to Chinese standard - easily surpasses the durability and site acceptance tests in the product standard

Available in a range of sizes in thickness (1mm ~ 8mm)

Easy to handle, install and process

Though bare silver is considered a poor solution due to its ability to tarnish and its inability to reliably adhere to surfaces like glass, a protected silver mirror coating can be applied. These coatings can be highly reflective dielectric layers that resist tarnishing and improve adhesion. Although it is possible that these protected silver coatings may be susceptible to damage from ultraviolet light, choosing specific dielectric overcoats of higher thicknesses may prevent this degradation.

As a coating for optical mirrors, silver may outperform traditional aluminum coatings. Researchers studying the Gemini telescopes have determined that a silver mirror coating is effective for observing infrared and visible spectrum wavelengths, however, the properties of silver may tend to over-absorb ultraviolet light. Although aluminum may be a better solution, hybrid coatings that combine silver and aluminum are being explored.

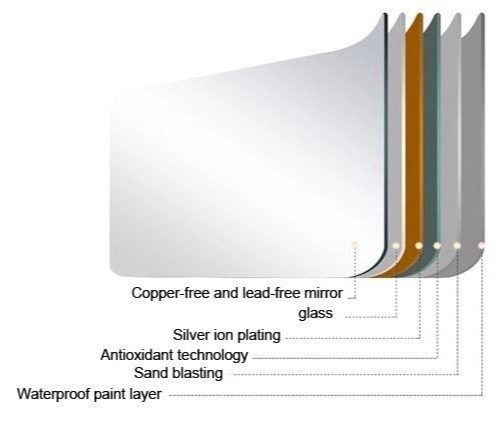

A copper free mirror is made through a chemical sedimentation process. As traditionally a sheet of specially treated silver is coated on quality float glass, followed by a sheet of special metal film instead of copper and this is then finished with two layers of paint for chemical and physical protection using a paint can produce a copper free high quality mirror.

The main benefit of copper free mirrors is the reduced corrosion. As discussed above, this is the rusting that appears beneath the surface of the coating and once this appears there nothing that can be done to get rid of it. RUNTAI Copper free & Lead Free mirrors are 3 times more resistance to corrosion than traditional mirrors. Other than the benefits of longer longevity of the mirror, copper free mirrors are also better for the environment. Without the harmful chemicals such as copper sulfate and lead in the manufacturing process, the production of these mirrors are significantly less harmful to the environment.

There is no way to tell by looking at a mirror if it is copper free. Sometimes this will be printed on the backing of the mirror. The best way to ensure a mirror is copper free is to ask the manufacturer or distributor of the product. RUNTAI Copper Free and Lead Free Mirrors are all made with utmost quality assurance to stand up to customer expectations.

Thickness: 1.5mm,1.7mm,1.8mm, 2mm, 3mm, 3.5mm, 4mm,4.2mm, 4.5mm, 5mm, 6mm, 8mm

Regular Sizes: 500*700, 600*900, 1000*700, 1000*800, 1220*900, 1220*914, 1220*1000, 1830*1220, 2440*1830, 3300*2140, 3660*2140 to the maximum.

we can do according to customer requirements for the back color and single and double coating of the layers of the Paints while processing Mirrors if they

can meet our MOQ (Minimum Order Quantity)

Applications

The RUNTAI Mirror Range can be used in many applications where high light

reflectance and a sense of increased space are important, such as:

Bars and restaurants

Shopping and leisure centres

Residential and commercial buildings

Furniture design

Product features summary

Superior light reflection of 94% on 4 mm thickness for RUNTAI ULTRA CLEAR MIRRORS

Excellent resistance to natural atmospheric corrosion

Higher corrosion resistance and improved protection to chemical attack from cleaners and certain adhesives than conventional mirrors

Easy to handle, install and process

Available in a range of thicknesses and sizes including 1.8mm,1.9mm, 2mm, 3 mm, 4 mm and 6 mm, etc (custom thickness and sizes are also available)

Environmentally friendly manufacturing process produces less waste and ensures

easier onward recycling

RUNTAI Safety Mirror is produced by attaching an adhesive protective plastic film on the back of mirror. It can prevent people from being hurt while mirror is breaking (broken) by accident. Almost all safety mirrors are produced with silver mirror

For an alternative, it also can be made of aluminum mirror.

Vinyl backed safety mirror is used to add dimension and light to your space with added safety benefits. The smooth vinyl film on the back of the mirror acts as a protective film, and if the mirror is cracked it stays together stuck to the film.

Applications Indoor use only

Sliding doors, Wardrobes, Mirror cabinets, Furniture, Fitness club, Gym, or other public areas

Any places where you use common silver mirror, you can also use safety mirror.

Specifications:

Thickness: 2mm to 8mm

Size: 1220 x 914mm, 1220 x 1830mm, 1524 x 2440mm, 1830 x 2440mm, 1830 x 3050mm etc.

Customized sizes available as per request;

Type of backing:

1. CAT I -- white PE glossy film;

2. CAT II -- white PP woven fabric film;

3. CAT III -- clear PE glossy film.

Cut down the development time with drag-and-drop website builder. Drop the blocks into the page, edit content inline and publish - no technical skills required.

Cut down the development time with drag-and-drop website builder. Drop the blocks into the page, edit content inline and publish - no technical skills required.

Choose from the large selection pre-made blocks - full-screen intro, bootstrap carousel, slider, responsive image gallery with, parallax scrolling, sticky header and more.

Choose from the large selection pre-made blocks - full-screen intro, bootstrap carousel, slider, responsive image gallery with, parallax scrolling, sticky header and more.

Normal Silver Mirror

Copper Free & Lead Free Mirrors.

Choose Clear for stunning clarity and to maximize the natural light bouncing around the room

Choose Clear for understated yet elegant look that sets your space apart from the rest.

Dark & Elegant, Black Mirrors are the height of luxury, ideal for decorative appliances.

Choose Bronze for a golden hue that can be used as a feature in modern styling.

*All colors are for reference only.. it will vary a little with different batch of productions. Tinted Mirrors depend on the Colors of the tinted color and will vary as per the color from different manufacturers of glass.

GOLDEN

PINK

GOLDEN BRONZE

EURO BRONZE

DARK BLUE

DARK GREY

PURPLE

DARK GREEN

FORD BLUE

F-GREEN